Laser Chiller for Cooling 3W-40W UV Lasers

Laser Chiller for Cooling 3W-40W UV Lasers

Blog Article

Do you know what is UV laser? UV lasers are achieved by using the THG technique on infrared light. They are cold light sources and their processing method is called cold processing. With a short wavelength, pulse width, and high-quality light beam, UV lasers enable precise micromachining by producing a smaller focal laser spot and minimizing the heat-affecting zone. UV lasers have high power absorption, particularly within the UV wavelength range and short pulse duration, resulting in quick material vaporization to reduce heat and carbonization. The smaller focus point allows UV lasers to be applied in more precise and smaller processing areas. Due to their very small heat-affecting zone, UV laser processing is classified as cold processing, which sets it apart from other lasers. UV lasers can penetrate materials and apply photochemical reactions during processing. Despite having a shorter wavelength than visible light, this characteristic enables UV lasers to achieve precise focusing, ensuring accurate high-end processing and remarkable positioning precision.

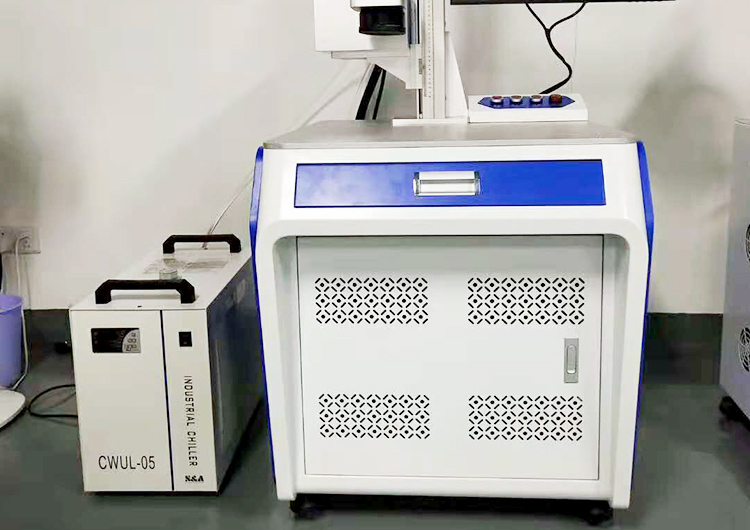

Due to its remarkable precision, UV laser is highly susceptible to thermal variations, where even the slightest temperature fluctuation can significantly impact its performance. As a result, the use of equally precise water chillers becomes essential to ensure the optimal operation of these meticulous lasers. TEYU S&A UV laser chiller is specifically designed for cooling 3W-40W UV lasers. It is characterized by ultra-precise temperature control (±0.1℃, ±0.2℃ or ±0.3℃) and stable cooling performance with two temperature control modes, including constant temp control mode and intelligent temp control mode. With the compact design, it is easy to be moved. In addition, it is equipped with multiple alarm protective functions, safeguarding both the chiller and the laser system.